99% Green!!!!!

We turn low-efficiency, polluting combustion-driven power plants into high-efficiency Oxygen, Water, Biomass and Electricity-producing factories. Get one to improve your city!

99% Green!!!!!

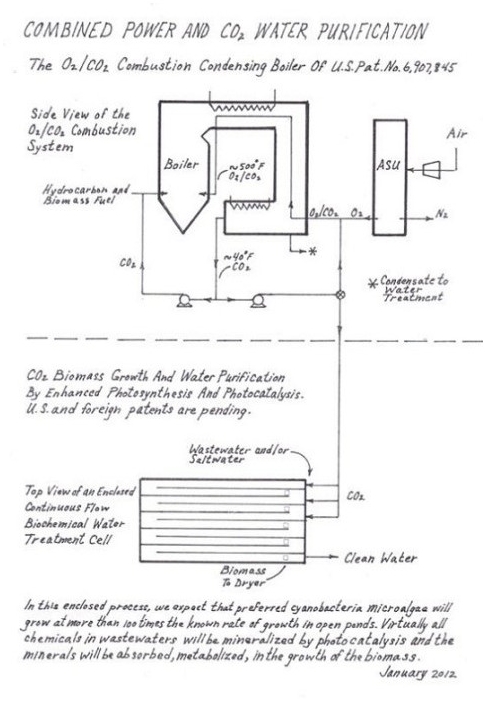

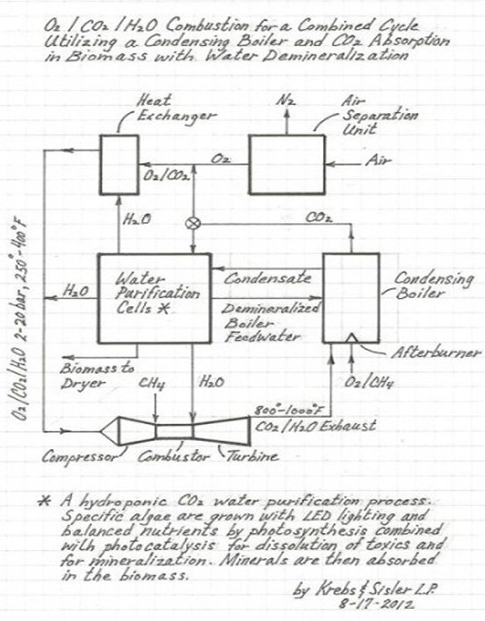

At www.TheOxygenFactory.net, we recycle carbon by burning hydrocarbons (coal, natural gas, petroleum coke), and your garbage to generate electricity, then capturing and separating the exhaust gases, one of which being the headline-grabbing greenhouse gas, CO2. Through enhanced photosynthesis, we are able to turn waste CO2 into Oxygen, Water, and Biomass, items vital for life on Earth. Additionally, a second exhaust gas captured is steam, meaning, beyond the water required at startup, our design is a net water producer. And we don't have any unsightly smokestacks or cooling towers, either!

99% Green!!!!!

www.TheOxygenFactory.net

September, 2014, Krebs & Sisler L.P.

Oxygen demand on Planet Earth continues to increase due to the breathing needs of now 7.3 billion humans and their need to oxidize increasing amounts of hydrocarbon fuels for energy. Our design will produce oxygen economically at large scale to head off future declines in this vital resource.

Oxygen is the main byproduct of recycling carbon dioxide (CO2) in the hydroponic biological growth of cyanobacteria like Spirulina. Cynobacteria, formerly known as blue-green algae, are autotrophs which require the nutrient CO2 for growth in visible light to produce biomass. The process is very slow in nature but rapid under controlled conditions as in our U.S. Patent No. 8,673,615. We developed this technology to make use of the CO2 recovered from power plants utilizing our O2/CO2 combustion condensing boiler system detailed in U.S. Patent No. 6,907,845.

CO2 is composed of 27% carbon (C) and 73% oxygen (O2) by molecular weight. Obviously the greatest economic value to be gained from the biological process in the 8,673,615 patent is to recover both the biomass and all of the oxygen. The biomass when dried is 50% carbon and has multiple uses for fuel, fertilizer, animal feed and a human food supplement. The oxygen may be released to enrich the air we breathe; or, it may be recycled through the power plant combustion process where the oxygen combustion method embodies the potentially emission-free condensing boiler.

This recycling of oxygen for fuel combustion is being estimated to reduce the cryogenic air separation requirement by about 40%, resulting in a large efficiency improvement. Or alternatively, the plant power output may be increased about 40% by adding more fuel and turbine/generator capacity.

The above processes will be adaptable to another technology we are developing called Rotary Kiln O2/CO2 Combustion with a Condensing Boiler. It will improve efficiency with lower capital and operating costs compared to current pulverized coal air-fired plants. It will have no emission problems.

99% Green!!!!!

For narratives (suitable for the public) on how our technologies can positively impact society: http://www.krebsandsislerlp.com/papers/

For more detailed information (technical bias) on the benefits and applications of our technologies: http://www.krebsandsislerlp.com/benefits/

To learn how to turn salt water into drinking water on a large scale at an affordable price: http://www.krebsandsislerlp.com/co2-desalinization/

To upgrade existing power plants: http://www.krebsandsislerlp.com/retrofitting/

To see design diagrams: http://www.krebsandsislerlp.com/

99% Green!!!!!

Our innovative technologies and dedicated team set us apart from others in the industry.

For additional information, please see www.krebsandsislerlp.com.